Fiber Optic Linear Heat Detection

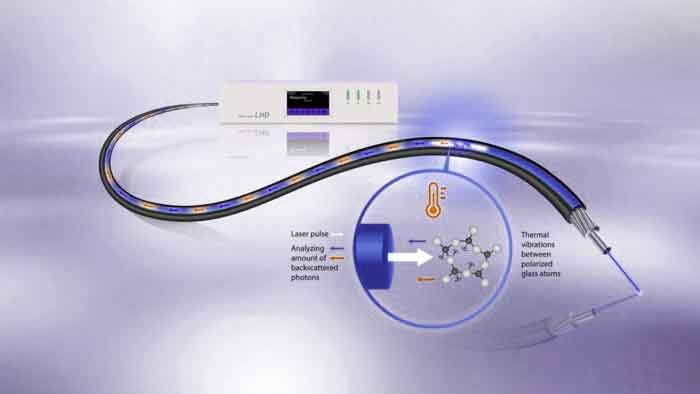

A Linear Heat Detection (LHD) system is intended to monitor and identify temperature changes along a sensor cable’s length. A fiber optic LHD employs standard fiber optic sensor cables, usually spanning several kilometers, serving as linear temperature sensors. These systems are fully distributed, meaning they respond to heat at any point along the cable in the same manner. This leads to a continuous temperature profile across the entire length of the sensor cable.

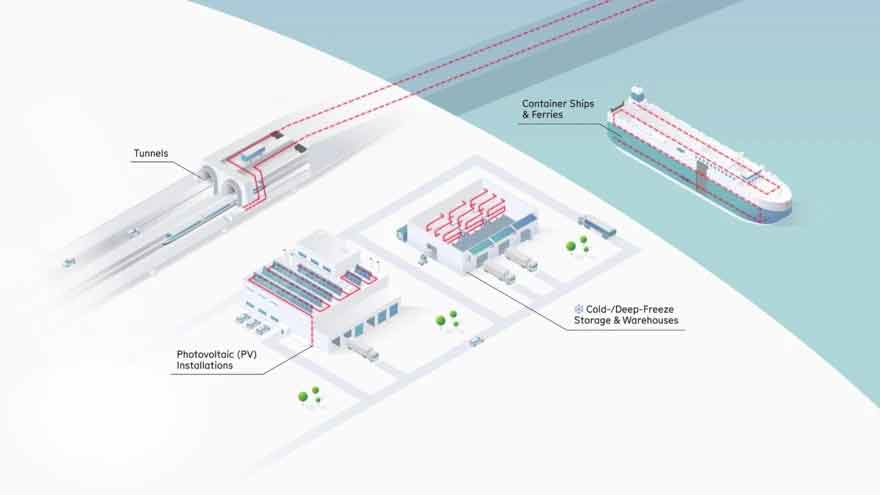

Fiber optic Linear Heat Detection (LHD) systems are designed to monitor and identify temperature fluctuations along a sensor cable that can extend for several kilometers. By employing certified fiber optic LHD cables as continuous temperature detectors, this system is capable of responding to heat at any point along the cable, effectively identifying hotspots and fires with exceptional accuracy. For instance, across a distance of 10 km, the system is capable of measuring 10,000 temperature points every 5 seconds, allowing for swift detection and precise data regarding the location, size, and progression of a fire. By ensuring vigilant and ongoing temperature monitoring over large distances, fiber optic LHD significantly improves fire safety for various critical infrastructures, including traffic and utility tunnels, parking garages, conveyors, cable trays, solar farms, and battery storage facilities.