Distributed Temperature Sensing

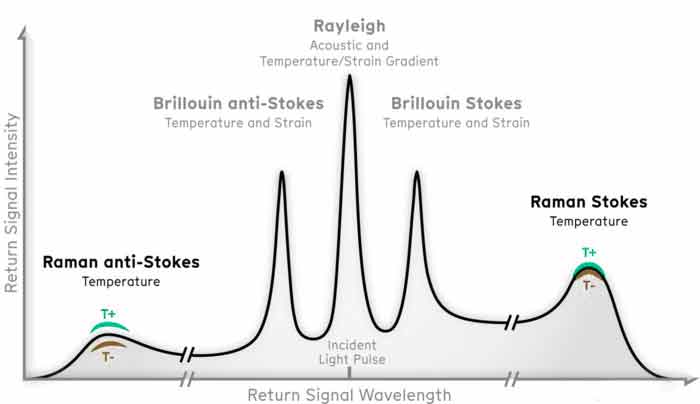

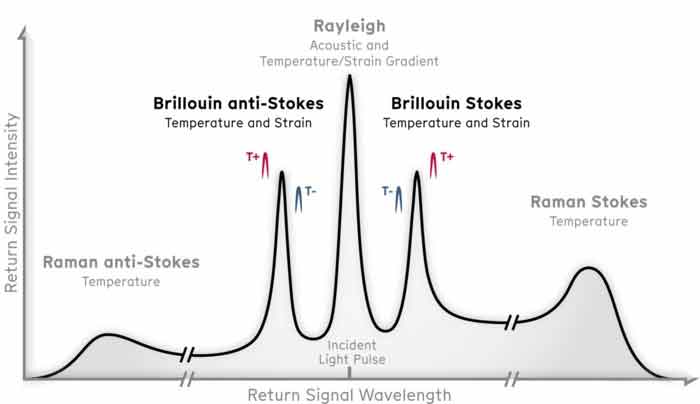

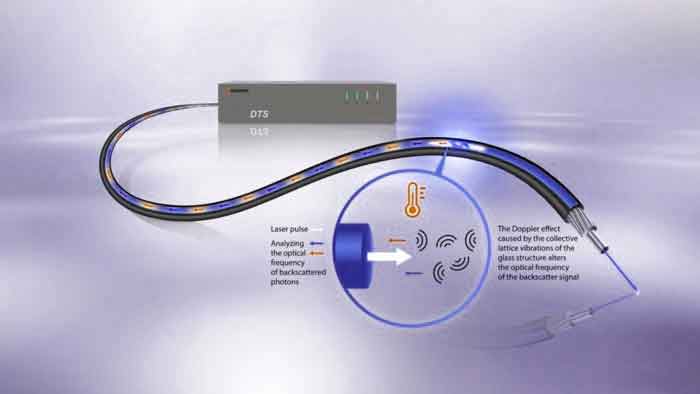

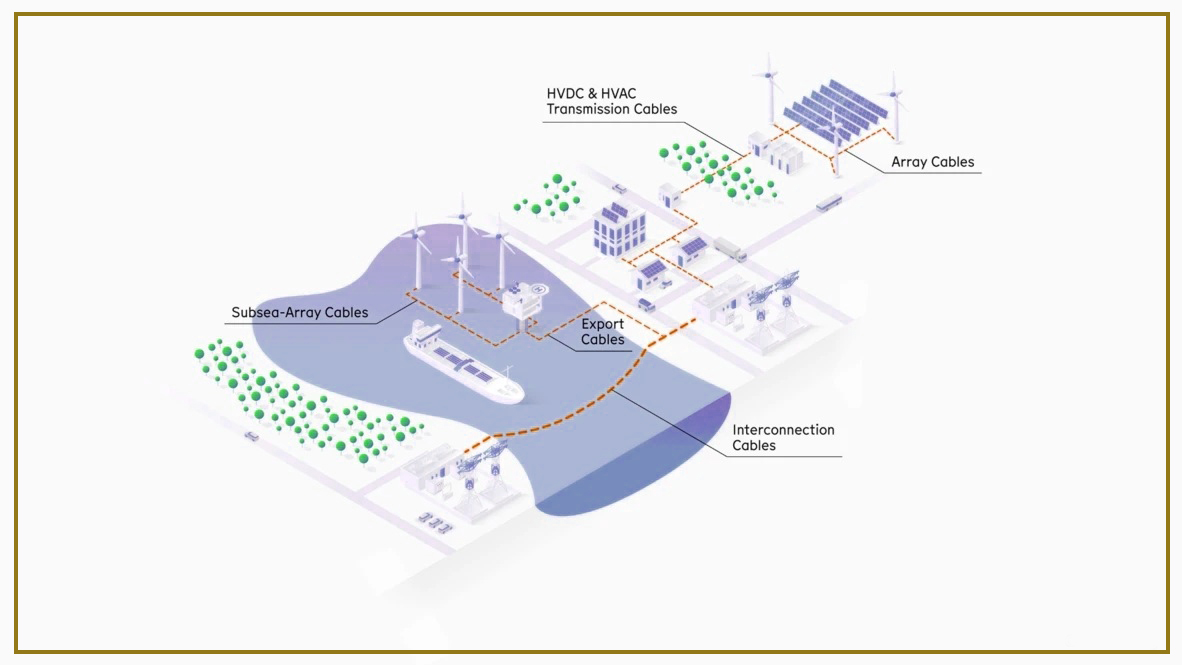

Distributed Temperature Sensing (DTS) systems offer precise temperature data for effective thermal monitoring, fire alarm systems, and condition evaluations by employing standard fiber optic cables. These optical fiber systems accurately assess the temperature profile of an asset by analyzing the interaction between light and the glass structure of the fiber. Real-time monitoring of an asset along the fiber optic cable provides essential information needed to initiate or modify preventive or corrective measures for assets like power cables, pipelines, or tunnels.