Distributed Acoustic Sensing

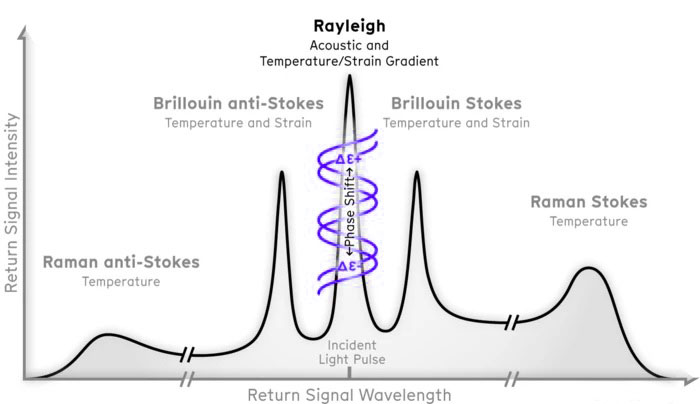

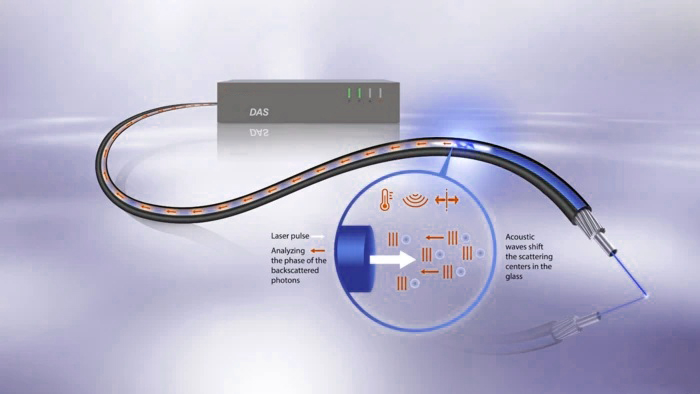

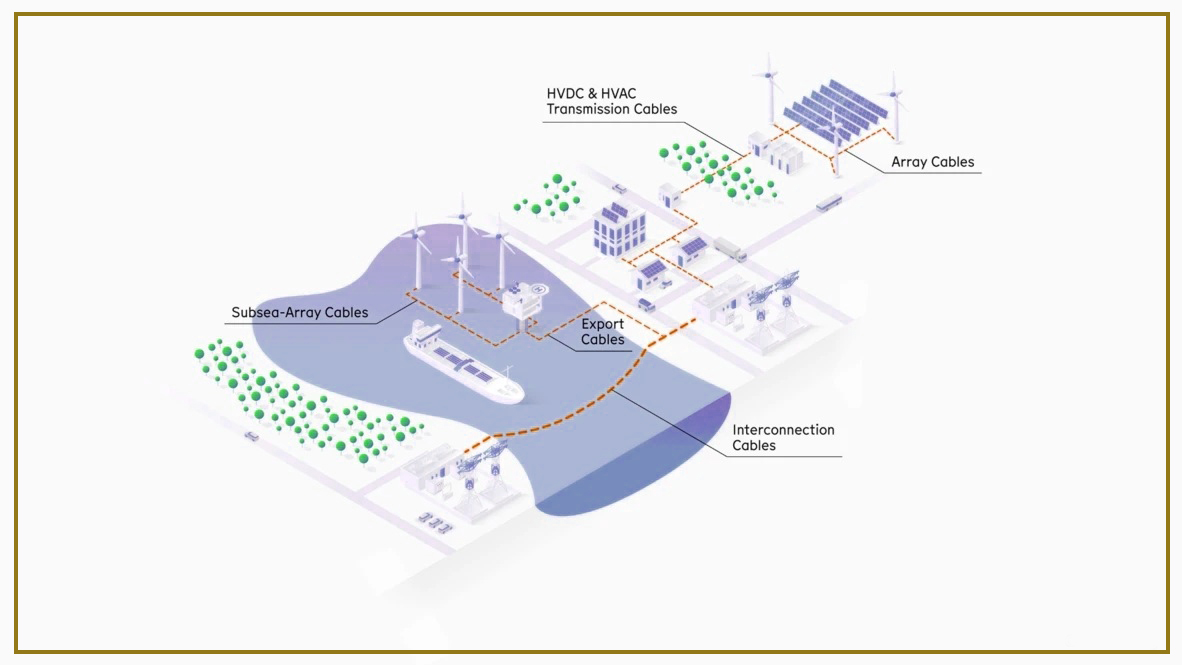

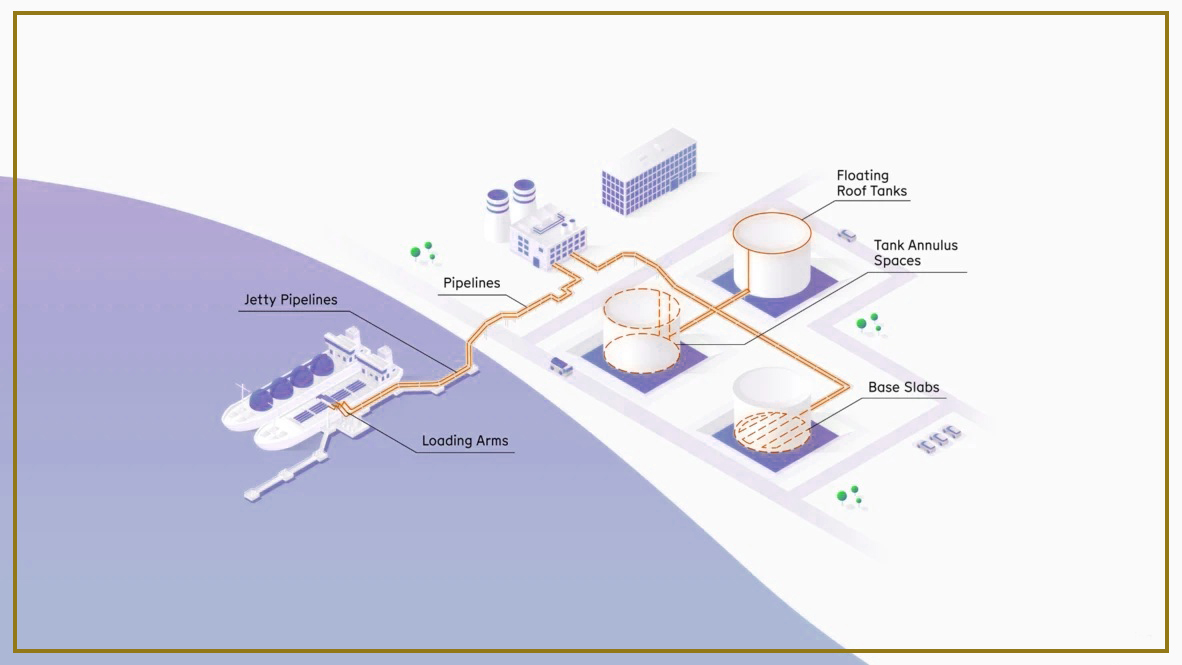

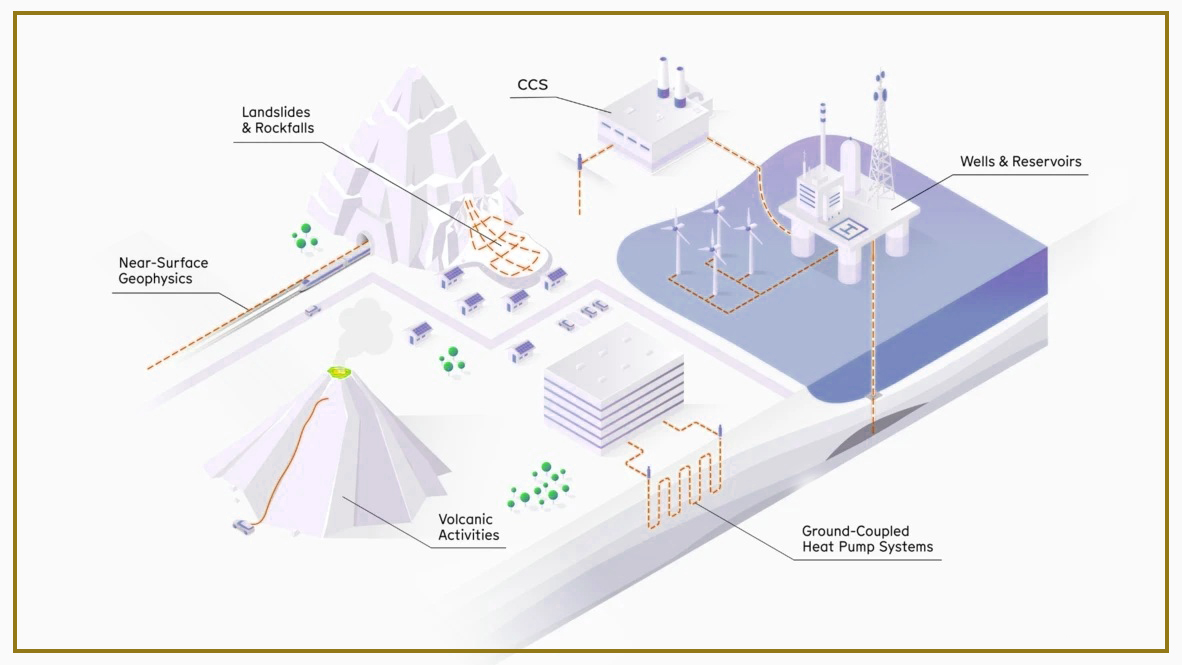

Distributed Acoustic Sensing (DAS) technology is capable of detecting changes in strain and vibrations along optical fibers. This sensitive method is employed for monitoring essential infrastructure, including power lines, pipelines, and railway tracks. The fiber optic cable acts as a distributed acoustic sensor, enabling ongoing measurements throughout its entire length, thus empowering operators or automated systems to make informed decisions and implement preventive or corrective measures as needed. Machine learning and artificial intelligence-based classification algorithms are utilized to detect, identify, and locate events such as pipeline leaks, faults in power cables, and intrusion incidents.