A blazing fire can have devastating consequences, posing risks to human life, damaging valuable infrastructure and assets, and causing prolonged downtimes. Fire protection becomes even more complex in environments affected by harsh conditions, where conventional solutions often fall short. Airway Security’s fiber optic Linear Heat Detection (LHD) is an ideal solution for monitoring special hazard applications in challenging environments, such as traffic tunnels, PV installations, parking garages, or in the manufacturing industry ensuring both safety and operational continuity.

Challenges & Opportunities

Industrial facilities often produce dirt, dust, moisture, and corrosive conditions during their operations, which can render traditional sensor technologies unreliable and prone to false alarms. Such false alarms can result in expensive disruptions, including the halt of production lines, tunnels, and, in severe instances, triggering costly fire suppression systems like deluge or high-expansion foam. In these environments, safety systems require prompt and dependable fire detection, particularly in larger facilities that entail intricate installation, commissioning, and increased maintenance requirements.

Fiber Optic LHD as a Solution for Fire Detection

By integrating phase and amplitude measurements, Airway Security’s unique 2P Squared technology experiences less interference from the signal fading typically seen in other C-OTDR systems. The DAS system developed by Airway Security delivers consistent performance throughout the fiber, ensuring high-quality measurements. Superior raw data forms the foundation for pattern recognition and machine learning algorithms.

Airway Security’s fiber optic Linear Heat Detection (LHD) technology presents an excellent option for fire safety in specialized high-risk situations and difficult environments. Our certified technology employs a fiber optic cable as a highly accurate, distributed heat sensor, effectively identifying fires in facilities subject to severe conditions. It delivers precise temperature profiles at intervals of a few seconds along the fiber optic cable, spanning distances that can reach several thousand meters.

Airway Security’s Linear Heat Detection System

Our LHD N45-Series is thoroughly tested and certified (EN (VdS), UL, ULC, FM, KFI, SIL2, IECEx, ATEX) with the industry’s fastest fire detection and lowest false alarm rate.

The LHD N45-Series withstands even the harshest conditions like:

- Dirt, dust and corrosive atmospheres

- High humidity and frequent temperature changes

- Solvent vapors and detergents

- Electromagnetic interference (EMI)

- Explosive environments due to gas or dust (ATEX / IECEx)

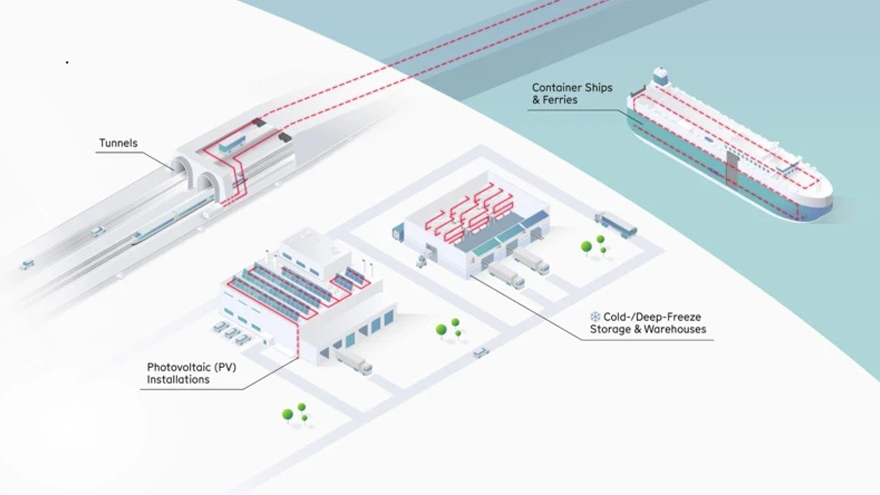

Application Fields of Fire Detection

Our technology extends into areas that other detection technologies (e.g. smoke, heat or flame detection) are unable to reach, providing coverage in environments, such as:

- Transportation Sector

Road and rail tunnels, metro stations, parking garages and aircraft hangars - Production & Storage Facilities

Coal storage, battery storage and warehouse facilities, conveyor belts and production areas, tank farms, food industry, refineries and chemical plants, false floors and ceilings - Energy Sector

Photovoltaic systems, battery storage, cable trays and transformers - Ships & Vessels

Container ships & ferries

Advantages of Our LHD N45-Series for Fire Detection

A fiber optic LHD system is designed to monitor and detect changes in temperature along the entire length of a passive fiber optic sensor cable. This allows our LHD solution to detect abnormal temperature changes and fires quickly and to precisely identify their location.

The LHD N45-Series fire detection system is immune to air flows, enabling it to precisely identify the location, size, and direction of an advancing fire. Unlike any other fire detection technology, it can tolerate temperatures reaching 750 °C (1400 °F) for a duration of 2 hours while maintaining monitoring functions. With Airway Security’s LHD solution, firefighting measures can be effectively implemented both prior to and during a fire incident.

In extensive infrastructures, the 4mm diameter fiber optic sensor cable typically traverses various locations under different temperature conditions. The LHD N45-Series allows you to set specific alarm criteria for numerous zones along the same cable run. Depending on the project requirements, the zones along the sensor cable can vary in length, can partially or fully overlap, or may have gaps between areas of interest. The system is resistant to dirt, dust, corrosive environments, organic vapors, and explosive settings. Airway Security’s offerings include certified sensor cables suitable for budget-conscious, standard, or specialized applications. All cables are designed to last around 30 years and require minimal maintenance.

Airway Security’s SmartVision software offers a visual dashboard for monitoring alarm zones, operational conditions, and real-time temperature readings, all through an intuitive graphical interface (GUI). It displays monitored assets and facilities in a mapped and color-coded format, indicating measured temperatures, alarm areas, fire locations, as well as the size and spread of fires. This provides personnel involved in emergency response with an immediate and precise overview on a single screen. SmartVision supports customized alarm zones and smoothly integrates various sensors, including Distributed Acoustic Sensing (DAS), DTS, CCTV, and more, into one cohesive platform.

Get in Touch With Our Experts

Airway Security, known for its reliable performance and ongoing innovation, provides a fully integrated, comprehensive solution crafted in Germany. Our team collaborates with you to choose the ideal combination of technologies that meet your needs.

Key Takeaways

- A single passive Ø 4 mm sensor cable, easy to install

- Immune to EMI, dirt, dust and humidity

- Maintenance-free, longest lifetime

- Largest coverage

- Functional even at 750 °C for 2 h according to IEC 60331-25

- Precise location of multiple fire events

- Fire size and spread monitoring

- Five different alarm criteria for quick detection in all 2,000 zones per channel

- Flexible zone and alarm configuration