Distributed Temperature & Strain Sensing

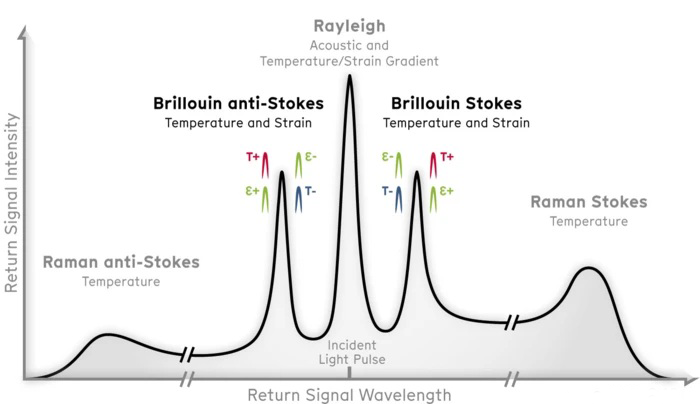

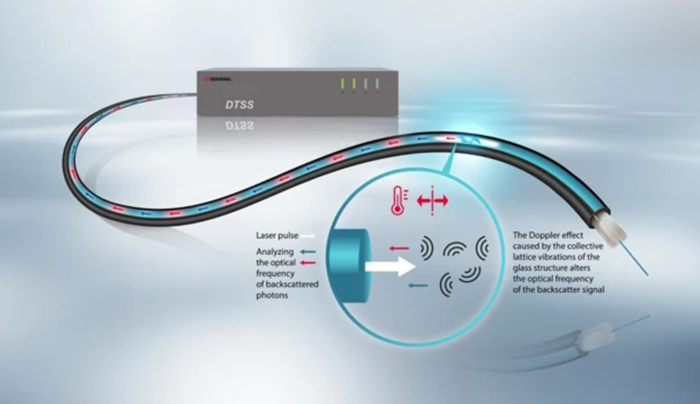

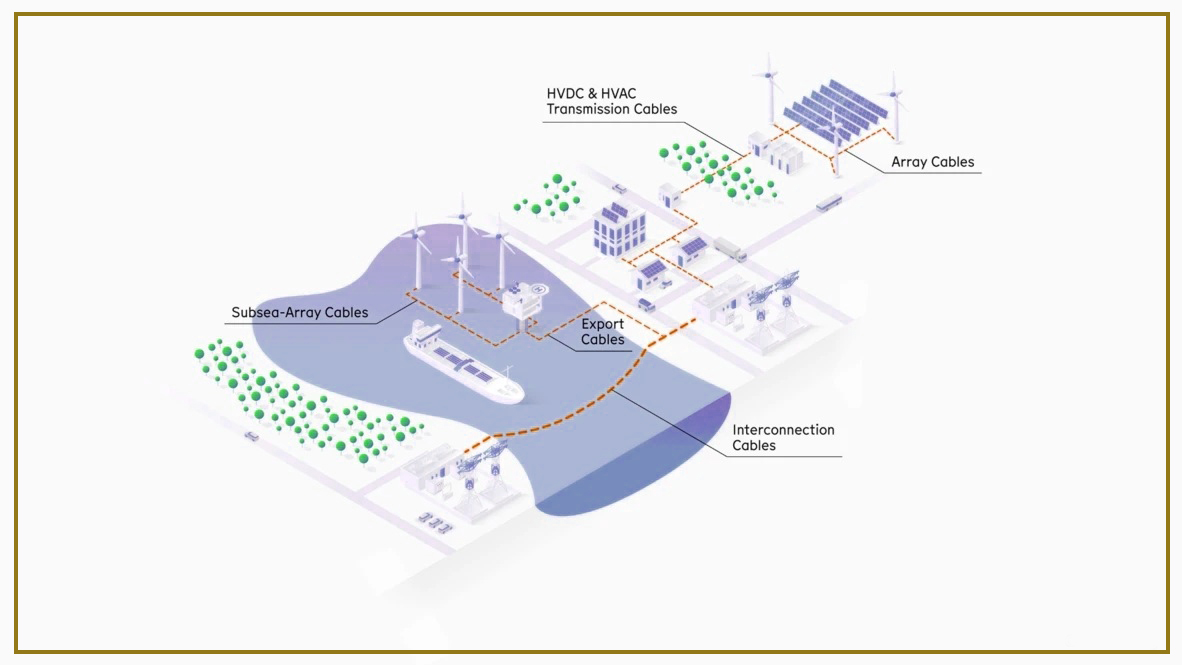

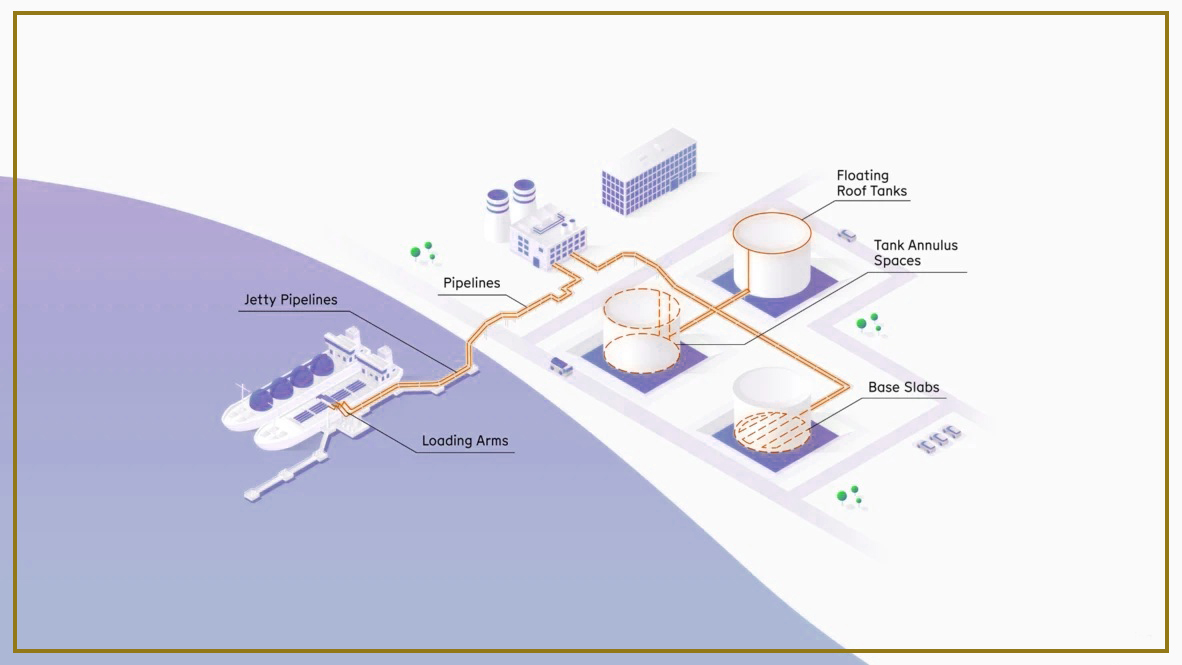

Distributed Temperature and Distributed Strain Sensing systems (DTSS) monitor temperature or strain along fiber optic cables to provide comprehensive asset oversight. This technology offers accurate temperature readings for monitoring purposes or detects mechanical strain, allowing for the identification of stress and potential structural issues. By examining the light interactions within the fiber optic cables, DTSS systems provide real-time information, facilitating preventive maintenance and corrective measures for essential assets like power cables, pipelines, and infrastructure (such as bridges, dams, and other buildings), thus ensuring thermal stability and structural integrity.